We are 100% superfine Tasmanian wool grower specialists, we select the best, grow the best and prepare the best premium superfine Tasmanian wool fleece for spinning and processing.

Ultrafine merino wool is defined as between 15.5 micron and finer and Superfine merino wool as 15.6 to 18.5 micron. At Baregamerino we grow soft luxurious superfine and ultrafine Tasmanian merino wool of between 14.2 to 16.5 micron.

Premium Tasmanian Superfine Merino

1. Passion

Premium Tasmanian Superfine wool is a result of passion for excellence, commitment to be the best and a holistic approach to our non mulesed merino sheep and the soft luxurious merino fibre they grow.

2. Genetics and Sheep Husbandry

It involves superior merino breeding and selection program, sound animal nutrition and merino sheep health. It requires a genuine commitment to merino wool fleece preparation of excellence to produce chemical free premium superfine Tasmanian wool fleece for spinning and processing.

3. Quality Control

As superfine and ultrafine merino wool grower specialists, at all our Tasmanian merino wool fleece is prepared using the Premium Classing Standard method as described in the Australian Wool Exchange (AWEX)Code of Practice in Preparation of Australian Wool Clips 2016-2018

Tasmanian Merino Fibre of Excellence

Superfine Merino Fleece length

Merino wool fleec e or staple length is one of the major determinates of shearing frequency at Baregamerino. Optimum merino fleece length varies on micron or fibre diameter, wool type, animal health and our customer’s wool for spinning needs.

e or staple length is one of the major determinates of shearing frequency at Baregamerino. Optimum merino fleece length varies on micron or fibre diameter, wool type, animal health and our customer’s wool for spinning needs.

15 to 16 micron superfine and ultrafine merino fleece length of wool for spinning or processing for our wool trade customers is 75-85mm, specialist merino customers require 85-95mm and craft hand spinners prefer a merino length of 100mm or greater.

Shearing Frequency for Superfine Merino Wool

Superfine merino wool grow rate is a factor of merino sheep genetics, merino nutrition and merino enterprise mix. That mix of superfine merino wethers and ewes will vary depending on the merino enterprise.

At Baregamerino, our ewes superfine merino fleece growth rate is on average 8 to 9 mm a month which determines the shearing frequency to more than once a year, closer to 3 shearings every 2 years.

Quality and Welfare Harvest for Tasmanian Wool

Shearing team comprises of trained and experienced shearers  skilled in the use of both conventional combs and cover combs.

skilled in the use of both conventional combs and cover combs.

The use of cover combs leave more than 7 mm of wool fleece as a protective covering on our Tasmanian merino after shearing instead of bare shorn.

We live on a mountainous island of Tasmania, at Australia’s most southern tip where sudden and unpredictable weather can occur especially during our transitional seasons of Spring and Autumn.

We live on a mountainous island of Tasmania, at Australia’s most southern tip where sudden and unpredictable weather can occur especially during our transitional seasons of Spring and Autumn.

The Wool Shed Team

The wool team is head by the wool classer, AWEX registered professional who guides the wool shed team in how the clip is to prepared, which covers management of the board (where the merinos are shorn) and on the wool table through to pressing of our superfine Tasmanian merino wool into bales for sale.

The wool classer approach to the classing of the clip is governed a number of factors including the AWEX code of practice of Australian Wool Clip, input from the wool grower, direct customer specifications, and finally the quantity and quality of the merino fleece in the clip to harvested.

The wool shed team includes shed hands experienced in board work and table work of extra wool preparation or double skirting skills for a quality outcome. The importance of the wool team skills cannot be understated in their role of quality preparation to produce premium superfine Tasmanian merino wool for spinners and buyers of specialist fibres.

Tasmanian Wool Premium Superfine Merino Fleece Preparation

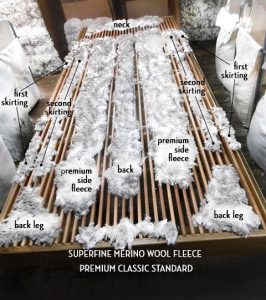

TRADITIONAL SUPERFINE MERINO WOOL PREPARATION is the first step in the process for a premium superfine merino wool fleece for spinning and processing.

- Every merino fleece that lands on the table is quickly appraised by the classer for staple strength, colour, and style which will dictate

the level or amount each individual fleece is skirted.

the level or amount each individual fleece is skirted. - The diagram shows the merino fleece with various areas to be skirted or removed, to leave only the premium section of the superfine merino fleece.

- It is important that these skirtings are identified correctly and accurately skirted from every individual merino fleece into their various lines leaving as much of the premium section of the fleece on the table.

- During skirting process, the classer and wool roller gauges the quality of the fleece by its handle, looking at uniformity of style, crimp, colour, wool length and level of vegetable matter and skirt accordingly.

- Finally, there will be two pieces of premium superfine Tasmanian merino fleece left on the table. Then classer brings them together to become one once again and checks strength and length of the fleece staple and with a last minute look over before allocating the superfine fleece to the correct wool bin.

All the merino wool will be placed in either a fleece line covering merino fleeces, necks and backs or non-fleece lines including pieces, broken, bellies, and locks.

Superfine and Ultrafine Merino wool fleece descriptions

Within each line of merino wool fleece the wool classer will add a description that best describes the wool in that line again accordin g to AWEX code of practice for Australian Wool Clip.

g to AWEX code of practice for Australian Wool Clip.

New descriptions for the top or best line of a superfine and ultrafine clip is XXXX SUP, replacing the traditional superfine description of EX SUP XXXX.

The same for the second best superfine merino fleece line description of AAAA SUP replacing the traditional EX AAA SUP and these descriptions will form part of the wool bale brand once the wool pressed.

BRANDING OF WOOL OF TASMANIA

Once shearing been underway for a couple of days the wool pressing begins under the eye of the wool classer. Wool pressing continues through to the end of shearing, with each bale weighed, documented and branded to according AWEX code of practice guidelines.

Branding of the bale includes the property brand, the wool description, bale number, classer id (unique stencil to each professional registered wool classer), a quality membership stencil such as Australian Superfine Wool Growers Association (ASWGA) and wool of Tasmania stencil brand onto the front of each bale of wool of the clip.

Tasmanian wool and Tasmanian merino has an identity is associated with high yielding bright superfine merino wool with low to little vegetable matter. Our superfine wool is grown on merino sheep on an island, surrounded by ocean that offers a layer of protection to our biosecurity that is considered enviable, clean and green. A wonderful image that embodies the spirit of the marvellous Tasmanian merino fibre we grow.

Tasmanian Wool and Superfine Merino Wool Shed Preparation

Shearing always transforms the rural quiet of the shed into a hive of activity.

- Prior to commencement of shearing the wool shed is swept, cleaned and setup in readiness of the team’s arrival.

- Paper work is sorted, accreditation information and forms identified, chemical free and non mulesed documents sourced, along with previous clip results and sales are located.

- The notice board outlines the mob breaks (ie stud stock, mob ages, rams, pregnant ewes, wethers) and the number to be shorn. Any relevant history including last crutching date is marked, brands to be removed, and any extra shed activity specific to this shearing noted as in midside sampling and fleece weighting.

- Is shearing going ahead as scheduled? Wet weather events prior to and during shearing can cause delays. Shearing maybe delayed by wet sheep on the previous property which in turn delays the shearing team for the next property and so on down the line, we all wait our turn.

- The afternoon prior to starting, the sheep enter the shed for a 7 am start the following day.

- There are mobs of merino sheep close by in readiness for shearing in the days ahead and any

scheduled health treatments or weighing is organised while they are around the yards.

scheduled health treatments or weighing is organised while they are around the yards. - The days that follow are full with merino sheep, shearing and shed team, merino fleeces, shearing machines, wool pressing, farm visitors and contractors that call in over this time.

- The day of the final cut out arrives and the shearers finish. The remaining merino fleeces and wool oddments are baled and stencilled, the shed tidied and the wool team depart.

Once again, the quiet of rural life descend on the wool shed as the last of the shorn merino sheep leave the yards to re-join their mob out in the paddock.

Premium Superfine Merino, Tasmanian Wool

Finally, our Tasmanian wool clip is baled and forwarded to the broker where samples from each lot are forwarded to AWTA for testing in preparation for the sale.

Meantime we reflect on the merino wool fleeces we have handled over shearing, look at how the season has reflected in their wool fleeces and the condition of our merino sheep health and general wellbeing off shears.

Once our superfine merino wool results have returned, decisions are made on what changes or alterations need to made, if any as we move forward into the next Tasmanian wool growing season.